The 6 Main Causes of Non-Conformance to ISO 9001

October 2, 2023

In today’s business landscape, adhering to international standards is crucial to achieve excellence and gain a competitive edge. This includes the ISO 9001, a quality management standard that provides a framework for organizations to demonstrate their commitment to delivering products and services that consistently meet customer requirements.

So to help you avoid any problems with the compliance of this standard, let’s take a look at the six major causes of non-conformance to ISO 9001 and discuss strategies to prevent them. But first things first, what is non-conformance in ISO 9001? Let’s get into it!

What is Non-Conformance with ISO 9001?

Non-conformance is a deviation from established quality management processes and procedures outlined in ISO 9001 and can result in negative consequences for businesses. This can manifest in various ways, such as:

- Failing to establish effective quality management processes.

- Failing to meet customer specifications.

- Overlooking the management processes.

- Neglecting to conduct internal audits.

- Or overlooking customer feedback.

It not only indicates a lack of compliance with the standard’s requirements but also poses risks to the quality of products or services. This is why when non-conformance is identified, it is crucial for organizations to report it, allowing for the corrective actions to be taken.

What You Can Obtain By Being Compliant with ISO 9001?

Compliance with ISO 9001 is essential for businesses for several reasons. Let’s take a look at a few of the main benefits that complying with this standard offers.

- It helps enhance customer satisfaction by ensuring consistent quality and performance.

- It provides a competitive advantage by demonstrating the company’s commitment to excellence and continuous improvement.

- It instills confidence in customers and stakeholders, leading to increased loyalty, and business opportunities.

- It can lead to cost savings through reduced rework, improving productivity and profitability.

Compliance with ISO 9001 not only enhances customer satisfaction but also provides a competitive advantage and cost savings for businesses. Which is why it is so crucial for companies to take this standard seriously.

However, to be able to comply with this standard and obtain these benefits, we need to further understand the main causes of non-conformance with ISO 9001. So, let’s get into it!

The 6 Main Causes of Non-Conformance to ISO 9001

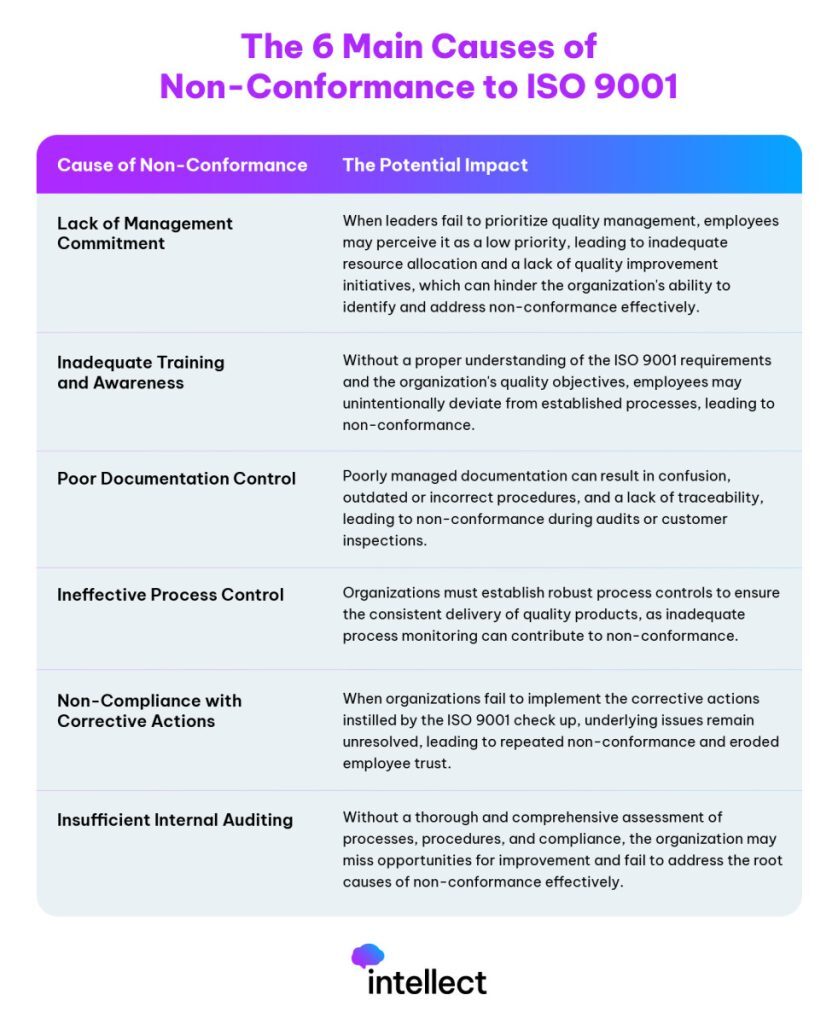

Eliminating non-conformance starts with understanding the underlying causes. Let’s explore the six main causes and their potential impact on the organization:

These are just six of the main causes that can lead to non-conformance. But you may be wondering, how much of an impact can non-conformance with this standard truly have on a business? Let’s discuss it!

The 3 Main Consequences of Non-Conformance on Businesses

Non-conformance to ISO 9001 can have far-reaching consequences for businesses. Let’s explore three major areas where non-conformance can negatively impact organizations:

1) The Financial Consequences

When products or services do not meet the required standards, it can often lead to:

- Refunds

- Costly rework

- Customer complaints

- And a potential loss of business.

Furthermore, non-compliance with ISO 9001 may lead to fines, legal liabilities, or the loss of certifications required for certain industries. These financial penalties can be significant and may even threaten the financial stability of the organization.

2) The Operational Disruptions

Non-conformance can disrupt business operations, leading to delays, inefficiencies, and decreased productivity. Moreover, addressing nonconformities often requires significant time and resources, which could involve:

- Conducting investigations

- Implementing corrective actions

- And retraining employees.

These activities take away valuable time and effort that could have been dedicated to core business activities such as innovation, expansion, or improving the customer experience.

3) The Damage to Business Reputation

In today’s interconnected world, news of poor-quality products or services spreads quickly through various channels, which can have long-lasting effects on a business’s ability to attract and retain customers.

When a business fails to meet the client’s expectations, they not only lose customers but also struggle to regain their trust. Rebuilding a damaged reputation can be a challenging and time-consuming process, requiring:

- Significant investments in marketing

- Public relations

- And customer outreach.

However, these aren’t the only strategies you can implement to secure compliance with ISO 9001. So let’s take a deeper look into some strategies to prevent non-conformance with this standard.

The 6 Strategies to Prevent Non-Conformance with ISO 9001

To prevent non-conformance and ensure ISO 9001 compliance, organizations must focus on implementing robust strategies that address the root causes. Here are six effective strategies:

Strategy 1 | Strengthen The Management’s Commitment

Leadership must demonstrate a strong commitment to quality management. To achieve this, establish a quality policy that clearly outlines the organization’s commitment to meeting ISO 9001 requirements.

After this, communicate it to all employees, making sure it has been reviewed to ensure its continued relevance. Don’t forget to provide guidance and support to employees, and allocate resources for training and development programs as it will ensure your commitment.

Strategy 2 | Enhance Employee Training

Providing comprehensive training on ISO 9001 requirements and the organization’s quality management system helps employees understand their role in achieving compliance. Ongoing training and awareness programs ensure that employees remain up-to-date, and can include:

- Workshops

- Seminars

- E-learning modules

- And on-the-job training.

By investing in employee training, organizations empower their workforce to contribute to the prevention of non-conformance and the overall success of the quality management system.

Strategy 3 | Improve Documentation Control

It is important to ensure that documents are easily accessible to employees, regularly updated, and controlled to prevent unauthorized changes. Here are a few ways you can achieve this:

- Implement a document management system that allows for centralized storage, version control, and easy retrieval of documents.

- Regularly conduct audits of the document control process, which can help identify areas for improvement and ensure compliance with ISO 9001 requirements.

- Provide training to employees on document control procedures.

By following these three simple steps you will be able to comply with the documentation necessary for the ISO 9001. But let’s take a look at another tip: streamlining process controls.

Strategy 4 | Streamline Process Controls

Organizations should implement robust process control measures, including:

- Defined metrics

- Monitoring systems

- And clear responsibilities.

Regularly reviewing and analyzing process data allows for timely identification and resolution of non-conformities. This can include the use of statistical process control techniques, automated data collection systems, and regular process audits.

Strategy 5 | Ensure Compliance with Corrective Actions

Corrective actions should be diligently implemented to address non-conformities. This involves:

- Identifying root causes

- Designing effective corrective measures

- And monitoring their implementation and effectiveness.

Regularly reviewing the effectiveness of corrective actions helps prevent recurrence. Once the root causes are identified, organizations should develop and implement corrective action plans that address the identified issues.

Strategy 6 | Enhance Internal Auditing Procedures

The audit process should follow a systematic approach, including:

- Planning

- Conducting the audit

- Documenting findings

- And reporting results.

Establishing a well-defined audit schedule, utilizing qualified auditors, and implementing a systematic audit process can help identify non-conformities and drive continual improvement. The findings from internal audits should be used to identify areas for improvement and drive corrective actions.

Why You Should Avoid Non Conformance to ISO 9001

Non-conformance to ISO 9001 can have devastating effects on businesses. By understanding the causes and implementing effective prevention strategies, organizations can safeguard their reputation, enhance operational efficiency, and ensure customer satisfaction.

ISO 9001 conformance is not just a stamp of approval; it is a commitment to quality excellence that drives continuous improvement and an ongoing journey that requires dedication, continuous improvement, and a culture of quality.