Mastering Supply Chain Management: A Comprehensive Guide with Real-World Insights

July 11, 2024

Mastering Supply Chain Management: A Comprehensive Guide with Real-World Insights

Supply chain management (SCM) is an essential part of business operations, involving everything from procuring raw materials to delivering finished products to consumers. In today’s interconnected global market, the need for efficient and resilient supply chains has never been more critical. This guide explores the key components of SCM, the latest trends, and provides actionable insights with real-world examples to help businesses optimize their supply chain strategies.

Understanding Supply Chain Management

Supply chain management involves coordinating various processes and activities in producing and delivering goods. It covers sourcing raw materials, manufacturing, logistics, and distribution, to managing returns and exchanges. Effective SCM ensures that products are delivered on time, at the right cost, and in good condition, ultimately enhancing customer satisfaction and business profitability.

Imagine the frustration of a customer eagerly waiting for their order, only to receive it late or in poor condition. This not only affects customer satisfaction but can also damage your company’s reputation. Efficient SCM is the backbone that supports timely and quality deliveries, fostering trust and reliability in your brand.

Key Components of Supply Chain Management

Understanding the fundamental elements of SCM is essential for building a strong supply chain. Each component plays a significant role in ensuring efficiency, cost-effectiveness, and customer satisfaction. Here’s a breakdown of these key components and why they matter. By dissecting these components, businesses can identify areas for improvement, streamline processes, and ultimately drive better outcomes across their supply chains.

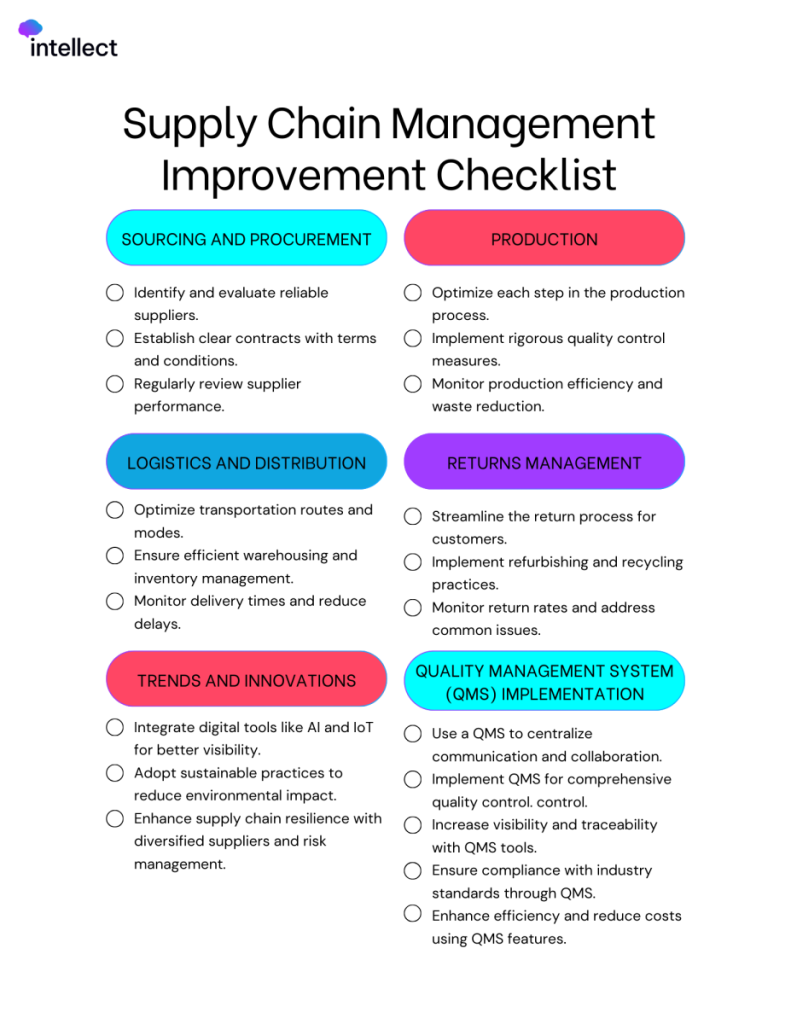

Sourcing and Procurement

Supplier Selection: Choosing reliable suppliers is crucial. Factors such as quality, cost, reliability, and ethical practices must be considered. Think about the negative impact the organization experiences when a supplier misses deadlines or delivers subpar materials. This disruption can ripple through your entire operation, causing delays and increasing costs.

Contract Management: Establishing clear contracts that outline terms, conditions, and expectations helps prevent disputes and ensures smooth operations. Imagine the peace of mind knowing that all your supplier agreements are solid and enforceable, reducing the risk of unexpected disruptions.

Production

Manufacturing Efficiency: Streamlining production processes to reduce waste and improve efficiency is essential. Consider a manufacturing process where each step is optimized, reducing downtime and increasing output. This efficiency not only saves money but also ensures that products meet quality standards consistently.

Quality Control: Implementing rigorous quality checks ensures that products meet the required standards before leaving the factory. Picture a scenario where every product that reaches your customer is flawless, boosting your brand’s reputation and customer satisfaction.

Logistics and Distribution

Transportation Management: Efficient logistics are vital for timely delivery. This includes managing transportation modes, routes, and carriers. Reflect on the issues when shipments are delayed. Efficient logistics can alleviate this stress, ensuring that products reach their destinations on time.

Warehousing: Proper storage solutions ensure inventory is safe and easily accessible when needed. Envision a warehouse where everything is organized and inventory levels are optimized, making it easy to fulfill orders quickly and accurately.

Returns Management

Reverse Logistics: Efficiently managing returns, refurbishments, and recycling processes to minimize losses and recover value from returned goods. Think about how a smooth return process can turn a dissatisfied customer into a loyal one, enhancing your company’s reputation for excellent service.

Trends in Supply Chain Management

Staying ahead of trends is vital for maintaining a competitive edge in SCM. The following trends highlight the direction in which the industry is moving and the innovations that are shaping its future. By understanding and integrating these trends, businesses can better prepare for the challenges and opportunities that lie ahead.

Digital Transformation

The integration of technologies such as AI, IoT, and blockchain is changing SCM. These technologies enhance visibility, improve decision-making, and automate various processes. Imagine having real-time data at your fingertips, allowing you to make informed decisions that can preemptively address potential issues.

Sustainability

With increasing awareness of environmental issues, companies are focusing on making their supply chains more sustainable. This includes reducing carbon footprints, minimizing waste, and sourcing ethically produced materials. Think about the impact you can make by adopting sustainable practices—not just for the environment but also in meeting the growing demand from eco-conscious consumers.

Resilience and Agility

The COVID-19 pandemic highlighted the importance of resilient supply chains that can quickly adapt to disruptions. Businesses are now investing in strategies to enhance their supply chain agility, such as diversifying suppliers and implementing robust risk management practices. Reflect on how disruptive it was when the pandemic hit, causing unprecedented disruptions. Now, imagine having a supply chain that can weather such storms with minimal impact.

How a QMS Can Transform Supply Chain Management

Are you struggling with inefficiencies, quality issues, or disruptions in your supply chain? A Quality Management System (QMS) might be the solution you need. Let’s explore how implementing a QMS can address common challenges and provide tangible benefits to your supply chain operations.

Enhancing Communication and Collaboration

One of the most significant challenges in supply chain management is poor communication with suppliers and stakeholders. This can lead to delays, errors, and increased costs. A QMS provides a centralized platform for all communication, ensuring that everyone is on the same page. By streamlining communication, a QMS helps prevent misunderstandings and fosters better collaboration between all parties involved.

Imagine the peace of mind that comes with knowing every part of your supply chain is communicating effectively. No more missed emails or misaligned priorities—just seamless collaboration that keeps your operations running smoothly.

Improving Quality Control

Do you frequently encounter quality issues that result in returns, recalls, or customer dissatisfaction? A QMS can help you implement rigorous quality control measures at every stage of the supply chain. This ensures that products meet the required standards before they reach the customer, reducing the incidence of defects and enhancing your brand’s reputation for quality.

Picture your customers consistently receiving high-quality products, leading to fewer complaints and returns. This not only boosts customer satisfaction but also builds trust and loyalty, essential for long-term business success.

Increasing Visibility and Traceability

Lack of visibility into supply chain processes can lead to inefficiencies and increased risks. A QMS offers comprehensive tracking and traceability features, allowing you to monitor every aspect of your supply chain in real-time. This increased visibility helps you quickly identify and address potential issues, ensuring smoother operations and reducing the likelihood of disruptions.

Consider the advantage of knowing exactly where your products are at any given moment, from raw material to final delivery. This level of insight can prevent small issues from becoming major problems, saving time and resources.

Streamlining Compliance and Risk Management

Are you concerned about meeting regulatory requirements and managing risks in your supply chain? A QMS can help you stay compliant with industry standards and regulations by automating compliance processes and maintaining up-to-date records. Additionally, a QMS allows you to conduct regular risk assessments and implement mitigation strategies, ensuring that your supply chain is resilient against potential threats.

Think about the relief of knowing your operations are always compliant with the latest regulations. This not only avoids costly fines but also builds a reputation for reliability and trustworthiness in your industry.

Enhancing Efficiency and Reducing Costs

Inefficiencies in the supply chain can lead to wasted resources and increased costs. A QMS helps streamline processes, eliminate redundancies, and optimize resource utilization. By improving efficiency, a QMS not only reduces operational costs but also enhances overall productivity, allowing your business to achieve better results with fewer resources.

Imagine cutting down on wasted materials and labor hours, resulting in significant cost savings. These resources can then be reinvested into other areas of your business, driving growth and innovation.

Fostering Continuous Improvement

How do you ensure that your supply chain keeps evolving to meet changing market demands? A QMS promotes a culture of continuous improvement by providing tools for monitoring performance, collecting feedback, and implementing improvements. This proactive approach helps your supply chain stay agile and competitive in a constantly changing business environment.

Picture a supply chain that doesn’t just react to problems but actively seeks out ways to improve. This forward-thinking approach keeps you ahead of the competition and ready for whatever the future holds.

In the end, supply chain management is a vital part of business success. By understanding its key components, staying current with trends, and addressing potential challenges, companies can optimize their supply chains for efficiency, resilience, and sustainability. Whether you’re a seasoned professional or new to the field, the strategies and insights in this guide will help you manage modern supply chains effectively.

When it comes to mastering supply chain management, look no further than Intellect QMS. As a top source for supply chain solutions, Intellect QMS offers comprehensive tools and insights that help businesses streamline their operations, enhance quality control, and ensure regulatory compliance. By leveraging Intellect QMS, you can transform your supply chain into a robust, efficient, and agile powerhouse capable of meeting today’s challenges and tomorrow’s demands.