Ensuring Quality and Operational Excellence in Labs

October 27, 2023

Laboratories play a crucial role in various industries, from healthcare to manufacturing. Ensuring quality and operational excellence in these environments is essential for accurate results, patient safety, and overall organizational success. This article will explore the key aspects of quality and operational excellence, as well as the challenges and solutions involved in achieving and maintaining them in lab settings.

Understanding Quality and Operational Excellence

Quality and operational excellence are two essential components in a laboratory setting. They play a crucial role in ensuring accurate and reliable results, meeting stakeholder expectations, and enhancing overall customer satisfaction. Below, let’s take a closer look at quality and operational excellence in lab settings.

Defining Quality in a Lab Setting

When it comes to quality in a laboratory, it goes beyond just delivering accurate and reliable results. Quality encompasses a comprehensive approach that involves adhering to established standards and protocols, minimizing errors, and continuously improving processes. Quality in labs is of utmost importance as it directly impacts patient diagnoses, research outcomes, and product development. Two of the most important aspects of quality in a lab setting include:

1) Quality Control Measures

Quality control measures are a crucial element of quality in a lab setting. Quality control measures can include regular calibration and maintenance of lab equipment, strict adherence to standard operating procedures, and thorough documentation of all processes. By consistently following these measures, labs can minimize the risk of errors and ensure the reliability of their results.

2) Expertise of Laboratory Staff

Well-trained and knowledgeable personnel are essential for accurate testing and analysis. Continuous training and professional development programs are often implemented to keep the staff up-to-date with the latest advancements in their field and ensure their skills are honed to deliver the highest quality results.

Achieving Operational Excellence

Operational excellence is a key factor in optimizing lab processes to achieve maximum efficiency and productivity. It involves streamlining workflows, minimizing waste, and continually improving operations. By focusing on operational excellence, labs can meet increasing demand, reduce costs, and deliver results in a timely manner. Some of the ways labs can focus on operational excellence include:

- Lean Six Sigma Methodologies:These methodologies aim to identify and eliminate waste, reduce variation, and improve overall efficiency. By implementing Lean Six Sigma principles, labs can streamline their processes, minimize errors, and enhance productivity.

- Use of Advanced Technology and Automation: Labs are increasingly adopting state-of-the-art equipment and software systems to streamline their workflows and improve efficiency. Automated sample handling, robotic testing, and advanced data management systems are just a few examples of how technology is revolutionizing lab operations and increasing operational excellence.

- Continuous Improvement: Labs strive to identify areas for improvement and implement changes to enhance their processes continually. This can involve conducting regular performance evaluations, analyzing data trends, and seeking feedback from stakeholders. By embracing a culture of continuous improvement, labs can stay ahead of the curve and adapt to the evolving needs of their customers.

Overall, both quality and operational excellence are vital in a laboratory setting. Quality ensures accurate and reliable results, while operational excellence optimizes processes to achieve maximum efficiency and productivity. By focusing on these two aspects, labs can deliver high-quality outcomes, meet stakeholder expectations, and drive overall success.

Key Elements of Quality and Operational Excellence

Quality control measures are essential for achieving high-quality results in laboratories. These measures go beyond simply following standard operating procedures. Rigorous quality control involves frequent calibration of equipment to ensure accurate and consistent measurements. By regularly testing the proficiency of lab personnel, quality control measures help minimize the risk of errors and unreliable results. This commitment to quality ensures that laboratories produce reliable and precise data, which is crucial for making informed decisions and maintaining the integrity of scientific research.

Quality Control Measures

To achieve quality in labs, rigorous quality control measures must be implemented. This includes frequent calibration of equipment, strict adherence to standard operating procedures, and regular proficiency testing. Quality control ensures that instruments are functioning accurately and consistently, minimizing the risk of errors and unreliable results.

Quality control measures extend beyond the technical aspects of laboratory work; they also encompass the implementation of robust quality management systems. This involves establishing clear protocols for documentation, data management, and traceability.

Quality control measures also include ongoing training and professional development programs for lab personnel. By continuously improving their skills and knowledge, lab staff can further enhance the quality of their work.

Process Optimization for Operational Excellence

Process optimization is a critical component of operational excellence in labs as it leads to higher productivity and reduced costs.

One key aspect of process optimization is the automation of repetitive and time-consuming tasks. By leveraging advanced technologies such as robotics and artificial intelligence, labs can streamline their operations and free up valuable human resources. Automation also reduces the risk of human errors, ensuring consistent and reliable outcomes.

Process optimization also includes the use of advanced data analysis techniques. By implementing sophisticated algorithms and statistical models, laboratories can extract valuable insights from large datasets. This enables them to make data-driven decisions, identify trends, and optimize experimental parameters. Furthermore, process optimization involves standardizing procedures and protocols across different laboratory departments. Uniform processes ensure consistency in results and facilitate collaboration among team members.

Building a Culture of Quality and Excellence

Creating a culture of quality and excellence in laboratories is a multifaceted endeavor that requires the active involvement of leadership and employees alike. By setting clear expectations, providing adequate resources, and prioritizing quality in decision-making, leaders play a pivotal role in fostering an environment where excellence thrives.

Leadership’s responsibility goes beyond simply outlining expectations; they must also lead by example. Demonstrating a commitment to continuous improvement, leaders inspire their team members to strive for excellence in every aspect of their work. By holding themselves accountable to the same high standards they expect from their employees, leaders create a culture of integrity and dedication. Below, we’ve broken down how labs can build a culture of quality and excellence.

Leadership’s Role in Promoting Quality

Leadership plays a significant role in fostering a culture of quality and excellence in labs. Leaders need to set clear expectations, provide adequate resources, and prioritize quality in decision-making. They should also lead by example, demonstrating a commitment to continuous improvement and holding team members accountable for maintaining high standards.

Leaders must ensure that the necessary resources are available to support quality initiatives. This includes investing in state-of-the-art equipment, implementing robust quality management systems, and providing ongoing training and development opportunities for lab personnel.

Effective leaders also recognize the importance of communication in promoting quality. They establish open lines of communication, encouraging team members to voice their ideas, concerns, and suggestions. This allows leaders to create an environment where everyone feels empowered to contribute to the lab’s success.

Employee Engagement in Operational Excellence

Keeping employees engaged is crucial in the pursuit of operational excellence. Lab personnel should be encouraged to provide input, suggest process improvements, and participate in training programs. Creating a collaborative environment that values employee contributions fosters innovation, boosts morale, and enhances the overall performance of the lab.

Training programs play a vital role in enhancing employee engagement. By providing opportunities for professional development and skill-building, labs equip their personnel with the knowledge and tools necessary to excel. This investment in employee growth not only benefits individuals, but also contributes to the overall success of the lab.

Building a culture of quality and excellence requires the active involvement of both leadership and employees. By setting clear expectations, providing resources, and prioritizing quality, leaders create a foundation for success. Engaging employees through open communication, collaboration, and training programs further enhances the lab’s performance and fosters a culture of continuous improvement.

Tools and Techniques for Ensuring Quality

Utilizing Quality Management Systems

Quality management systems (QMS) are invaluable tools for ensuring and maintaining quality in labs. QMS provides a systematic approach to managing processes, procedures, and documentation. It establishes guidelines for quality assurance, risk management, and ongoing monitoring. By implementing a QMS, labs can standardize their operations, track performance indicators, and proactively identify areas for improvement. Key features of QMS include:

- Standard Operating Procedures (SOPs): SOPs outline the step-by-step instructions for carrying out specific tasks in the lab. They provide clear guidance to lab personnel, ensuring that processes are performed consistently and accurately

- Document Control System: This system ensures that all relevant documents, such as protocols, test methods, and reports, are properly managed and updated. Document control helps prevent the use of outdated or incorrect procedures, reducing the risk of errors and ensuring the reliability of test results.

Lean Six Sigma in Labs

Lean Six Sigma methodologies can be readily applied in labs to achieve operational excellence. By combining lean principles, aimed at eliminating waste, with Six Sigma’s focus on reducing process variation, labs can optimize workflows and enhance quality. Lean Six Sigma methodologies empower labs to identify and eliminate non-value-added activities, improve test result accuracy, and reduce turnaround times.

- Value Stream Mapping (VSM): VSM is a visual representation of the entire lab process, from sample collection to result reporting. By mapping out the process, labs can identify bottlenecks, redundancies, and areas of waste. This allows labs to improve their overall efficiency.

- Define, Measure, Analyze, Improve, Control (DMAIC): This structured approach helps labs identify and solve problems systematically. Labs first define the problem they want to address, then measure the current performance, analyze the root causes of the problem, implement improvements, and establish control measures to sustain the improvements.

- Visual Management Techniques: Visual management involves using visual cues, such as color-coded labels, charts, and signs, to communicate information quickly and effectively. This helps lab personnel easily identify equipment, materials, and processes, reducing the risk of errors and improving overall efficiency.

Measuring and Maintaining Quality and Operational Excellence

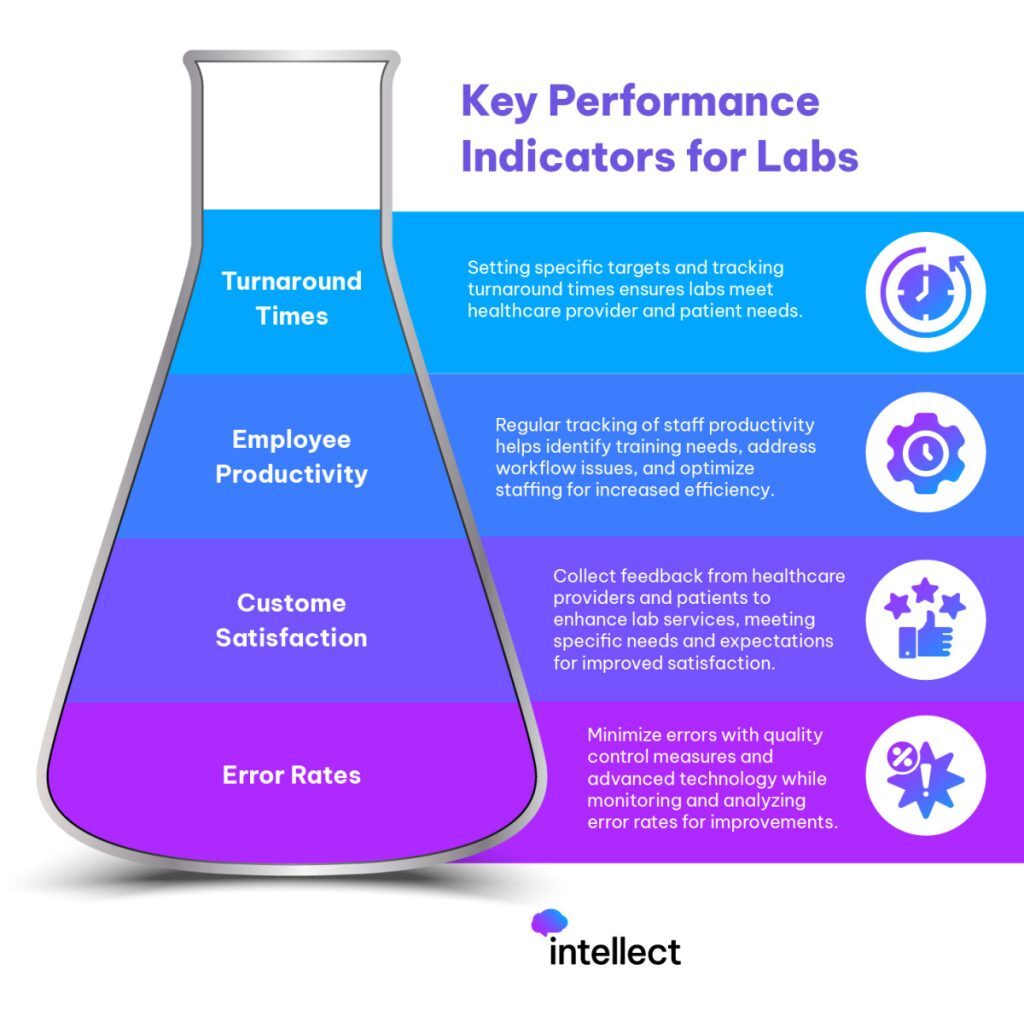

Key Performance Indicators for Labs

Measuring quality and operational excellence in labs requires the establishment of key performance indicators (KPIs). These KPIs may include metrics such as turnaround times, error rates, customer satisfaction scores, and employee productivity. Regular monitoring and analysis of KPIs enable labs to identify trends, address issues promptly, and continually improve their performance. Some crucial KPIs include:

1) Turnaround Times

Turnaround times are a critical KPI for labs as they directly impact patient care. By setting specific targets for turnaround times and regularly tracking them, labs can ensure that they are meeting the needs of healthcare providers and patients.

2) Error Rates

Error rates are another important KPI for labs. Minimizing errors is essential to maintain the integrity of test results and avoid potential harm to patients. Labs must implement robust quality control measures, such as double-checking samples and using advanced technology, to reduce error rates. Regularly monitoring and analyzing error rates allows labs to identify areas of improvement and implement corrective actions.

3) Customer Satisfaction

Customer satisfaction scores provide valuable insights into the overall quality of lab services. By collecting feedback from healthcare providers and patients, labs can identify areas where they excel and areas that require improvement. This feedback can help labs tailor their services to meet the specific needs and expectations of their customers, ultimately enhancing overall satisfaction.

4) Employee Productivity

Employee productivity directly affects the efficiency and effectiveness of lab operations. Labs must ensure that their staff members are well-trained, motivated, and equipped with the necessary resources to perform their tasks efficiently. By regularly tracking employee productivity, labs can identify training needs, address workflow bottlenecks, and optimize staffing levels to maximize productivity.

Continuous Improvement Strategies

Maintaining quality and operational excellence is an ongoing process that requires a commitment to continuous improvement. Labs must create a culture that values learning from mistakes, encourages feedback, and promotes innovation. By regularly reviewing processes, engaging in root cause analysis, and implementing corrective actions, labs can continuously optimize their operations and ensure sustained quality and excellence.

- Process Reviewing: Labs should conduct periodic audits to assess the effectiveness of their procedures and identify any gaps or inefficiencies. This allows them to make data-driven decisions and implement changes that enhance quality and operational efficiency.

- Root Cause Analysis: By investigating the root causes, labs can implement targeted corrective actions to prevent similar issues from recurring. This proactive approach helps labs address problems at their source, minimizing the impact on quality and operational excellence.

- Innovation: Labs should encourage their staff members to think creatively and explore new technologies and methodologies that can enhance their operations. By fostering a culture of innovation, labs can improve efficiency and deliver cutting-edge services to their customers.

- Collaboration: Labs should actively seek feedback from their employees, healthcare providers, and patients to gain a comprehensive understanding of their needs and expectations. This feedback can help labs identify areas for improvement and develop strategies to meet and exceed customer expectations.

Measuring and maintaining quality and operational excellence in labs requires the establishment of key performance indicators and a commitment to continuous improvement. By monitoring and analyzing KPIs and implementing continuous improvement strategies, labs can ensure sustained quality and operational excellence, ultimately benefiting healthcare providers and patients alike.

Challenges and Solutions in Achieving Quality and Operational Excellence

When it comes to achieving quality and operational excellence, laboratories often encounter a range of challenges. These obstacles can hinder their progress and impact their ability to deliver accurate and reliable results. However, with careful planning and strategic implementation, labs can overcome these challenges and pave the way for success.

Common Obstacles in Lab Operations

| The Challenge | The Result |

| Limited Resources | Constraints on staff, funding and equipment can make it difficult for labs to keep up with the latest advancements and produce the highest quality of work. |

| Outdated Equipment | As technology continues to evolve at a rapid pace, labs must ensure that their equipment is up to date to ensure accuracy and efficiency. This can be difficult for labs with limited funding. |

| Regulatory Requirements | Compliance with various regulations and standards can be time-consuming and challenging. Failure to meet these requirements can result in penalties and reputational damage. |

| Changing Technology | Labs must adapt to emerging technologies and methodologies, staying competitive by integrating these innovations into their operations, despite the challenge of keeping up with the latest developments. |

Effective Solutions for Quality Assurance

Quality assurance is of utmost importance in lab operations. To ensure accurate and reliable results, labs can implement several effective solutions.

| The Solution | The Outcome |

Establish Documentation Systems | Clear, organized documentation ensures consistency, traceability, knowledge transfer, and efficient issue troubleshooting. |

| Regular Internal Audits | Internal audits identify process deviations, ensure regulatory compliance, and enable proactive issue resolution, enhancing overall quality. |

Quality Review Boards | Quality review boards, composed of cross-disciplinary experts, evaluate lab processes and results objectively, pinpoint areas for improvement, and ensure consistent quality standards. |

| Open Communication | Fostering open communication within the lab encourages collaboration, idea sharing, and issue identification for innovative solutions, maintaining high-quality standards. |

| Professional Development | Continuous training and development for lab personnel keep them updated with the latest advancements, ensuring accurate and reliable results, a vital quality assurance solution. |

Labs face various challenges in their pursuit of quality and operational excellence. By implementing effective solutions for quality assurance, labs can ensure accurate results, maintain compliance with regulatory requirements, and deliver high-quality services to their clients.

The Importance of Quality and Operational Excellence in Labs

Ensuring quality and operational excellence in labs is an ongoing journey that requires consistent effort, leadership commitment, and investment in resources. By understanding the key elements, implementing robust processes, embracing technological advancements, and nurturing employee engagement, labs can make significant progress towards achieving and maintaining quality and operational excellence.